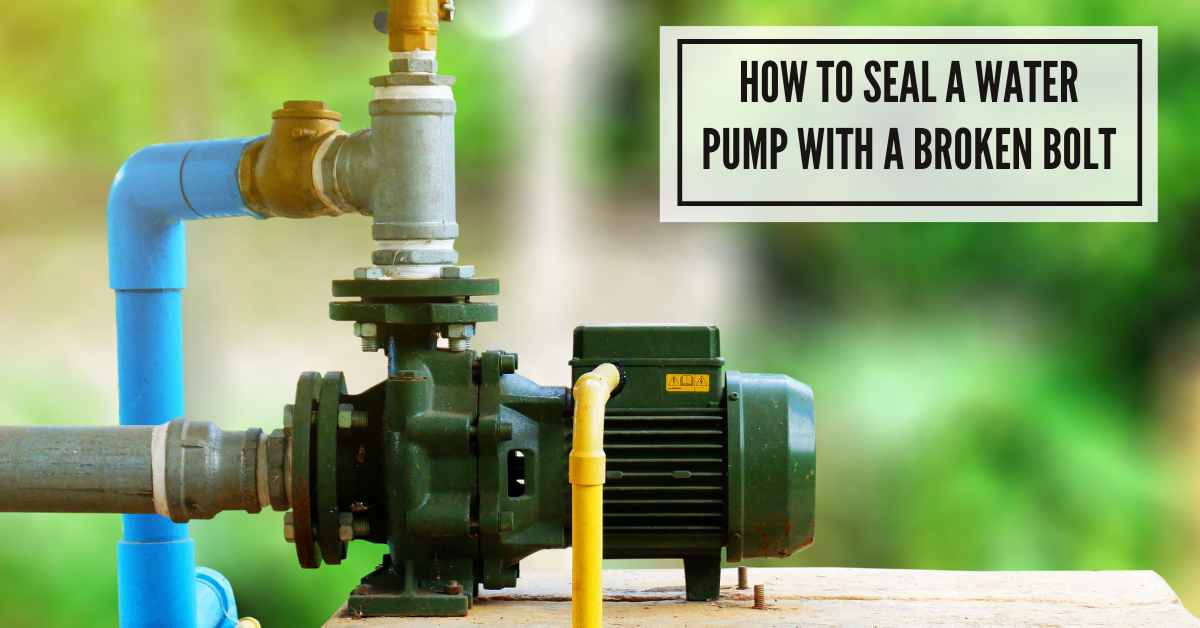

How To Seal A Water Pump With A Broken Bolt

Place the sheared-off piece of the nut in its original location and then superglue it. Weld inside the nut carefully to its upper part. Then, clean all the crucial components and seal the pump housing using a silicone-based sealer. Finally, tighten the bolts just right.

When it comes to ensuring the smooth functionality of a water pump, keeping it sealed is mandatory. If your nuts have holes or damage, you might wonder how to seal a water pump with a broken bolt. This article will give you a clear overview of this topic.

Will a Water Pump Leak if A bolt is Missing?

A water pump must have all the necessary bolts to secure the components tightly. Any missing bolts may cause leakage issues as they cause uneven pressure on the mating surface.

Plus, it may fail to maintain a secure and stable connection between different parts of the water pump.

The motor won’t remain at a constant temperature due to improper functionality. It will fail to keep an optimum operating temperature.

Besides, the engine may overheat due to leakage in the coolant. One or several components may break if it continues for a long time. Or, at worst, the entire engine may fail to start.

Can You Seal A Water Pump Leak?

Sealing a water pump can solve the leakage problem if it has more minor leaks. You can use sealant paste for this purpose.

But if the leaks are massive, sealant paste can’t alone solve the problem. You must use additional sealants for any water pump with larger leaks.

Even if you seal a water pump with bigger holes, it will lose its effectiveness over time. You will have to reseal the leaks more frequently.

What Causes Broken Bolts In Water Pump?

Water pumps may have one or several broken bolts for different reasons. They will fail to thread through the water pump and bond well with the pump housing.

One of the common reasons is over-torqued bolts. The main part of a water pumping machine’s nuts are made of hard steel.

But its outer parts have soft aluminum. Over-torquing the bolt can cause stripping or breaking of the threads in the connected part or nut.

Besides, corrosion, vibration, and over-tightening can also break the bolt faster. Bad-quality nuts are more likely to lead to breakage within a short time.

Can You Seal A Water Pump With A Broken Bolt?

It depends on how much damage the broken nut or bolt has. When drilling out the nuts of a water pump, you must precisely align the drill to remove only the bolt without damaging surrounding components.

The surrounding area of the water pump bolt has soft aluminum. If you accidentally hit the spot, it will cause significant damage to the nut. Any water pump bolt with crooked holes is less likely to create a secure seal.

However, sometimes, you may have instantly stopped after drilling out the soft aluminum. In such a case, it will cause minimal damage. After sealing the water pump properly, you may run it with a broken bolt.

How Do You Seal A Water Pump With A Broken Bolt?

If the sealant of your water pump is damaged, you must reseal it to prevent water from entering the pump. Not changing the sealant on time will lead to the poor performance of its engine.

The engine will overheat more often. It will compromise the water pump function. The following are the steps to follow to seal a water pump with a broken bolt.

Step: 01— Repair The Broken Bolt

The first important task is preparing the broken bolt. If you have the sheared-off nut piece, attach it to its original location. Then, use super glue to secure its place.

Weld the inside of the nut carefully to the upper part. Let it cool down for a few hours.

Once the bolt becomes cool enough, use a wrench or spanner to take it out. But if the bolt is completely damaged, it is best to install a new one.

Step: 02— Clean All The Important Components

After extracting the repaired bolt, keep it in a safe place. Clean the area thoroughly to remove debris, old gasket material, and coolant residue.

If the impeller has too much dirt, use a toothbrush or soft brush to scrub it gently.

You can use Triple7 Eco-Scale to remove limescale, calcium, rust, barnacles, and crustaceans from the water pump casing.

Finally, reassemble all parts of the water pump sequentially. Make sure they fit perfectly on each other.

Step: 03— Sealing The Water Pump Housing

There is a gap between the water pump cover and the engine holder. Sealing this gap is necessary to create a barrier enabling the rotating shaft to enter the pump’s internal wet area without any fluid leakage.

Silicone-based sealers are one of the best choices for sealing a water pump’s housing. Apply the sealant in all areas where you notice any gaps. Allow it to dry appropriately based on the manufacturer’s instructions.

Step: 04— Tightening The Bolts

Once the sealant is fully cured, you can insert the bolts in their original location. Avoid using any Teflon tape if you use your vehicle heavily. This will otherwise melt the tape and cause a malfunction in the water pump.

Now, tighten the screws properly. Use a socket or torque wrenches to tighten the bolts just right until you hit the sweet spot. If your water pump has smart bolts, it will change its red dot to blue.

What Can I Use To Seal A Water Pump?

Water pumps face different temperatures and pressure variations. Silicone-based sealants are highly heat resistant, flexible, and durable.

Hence, high temperatures and pressure fluctuations will cause minimal harm to the seal. The sealant will be long-lasting and effective to prevent fluid leakage.

RTV silicone comes in handy if you want a faster cure. It dries quickly at room temperature.

If you want a temporary solution, epoxy resins are also good to go. This strong adhesive can fill up cracks, holes, or gaps. But make sure to use several layers to get the best result.

Tips For Extending A Water Pump Lifespan

- Regularly clean the water pump. Keep it free from dirt, grease, and other contaminants.

- Protect the water pump from humidity and condensation to avoid building up corrosion.

- Use a correct, high-quality sealant to withstand extreme temperatures and chemicals.

- Monitor how intense the vibration is. Call an expert to diagnose the problem if it is too much.

- Make sure all the parts are aligned and positioned correctly. They might be misplaced after a specific time.

- Change your engine’s water pump after every 60,000 to 100,000 miles. Monitor the lubricant level and refill it once it goes below the minimum line.

FAQ’s

What are the signs of a faulty water pump seal?

Keep an eye out for little puddles of coolant, an unusually warm engine, odd noises, or rust in your coolant – these are telltale signs of a seal needing some love.

Can I replace a broken bolt myself or should I seek professional help?

If you’re handy with tools and feel confident, go ahead and replace the bolt yourself. But if it seems daunting, there’s no harm in calling in a professional to ensure everything is just perfect.

How often should I inspect my water pump for potential issues?

Give your water pump a yearly check-up or follow the heartbeats of the manufacturer’s schedule to keep it running smoothly.

What type of sealant is best for water pumps?

Opt for a silicone-based gasket maker or RTV sealant; they’re like a warm hug for your water pump, keeping it sealed and secure.

Are there any specific techniques for removing a severely corroded bolt?

Treat a stubborn, corroded bolt with some penetrating oil, gentle warmth, a bit of tapping, or a bolt extractor – a little patience here can work wonders.

Conclusion

A water pump is a vital component to keep the engine at a constant temperature regardless of the temperature. But your engine will overheat and trigger other issues if it doesn’t function properly.

You must keep the seal of the water pump airtight and watertight. If the broken bolt is repairable, repair it. Otherwise, get a new one. Hopefully, the above guideline has given you a clear picture of how to seal a water pump with a broken pump.

I am Robert Sandin, a professional sealing expert with a diverse range of expertise. From concrete to various other materials, I possess in-depth knowledge and experience in the art of sealing. On my website, I offer valuable tips and expert recommendations on sealing techniques and products for different materials. Whether it’s concrete, wood, metal, or more, I am committed to providing you with the guidance you need for successful sealing projects.