How to Seal around Metal Building Windows: Airtight Tips!

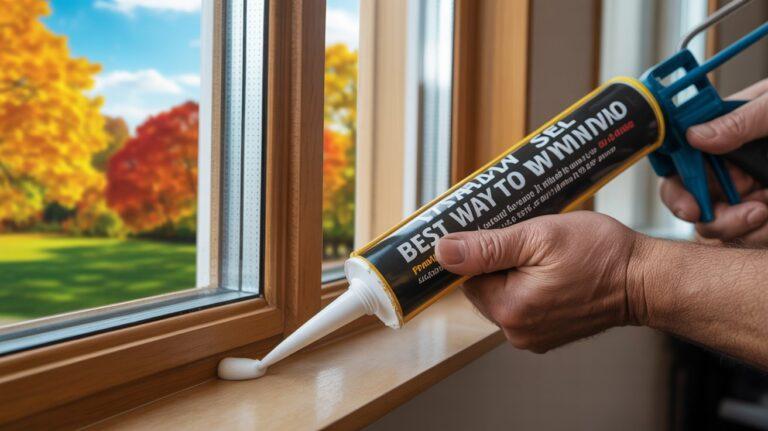

To seal around metal building windows, use a quality caulking compound and backer rod. Ensure the sealant is compatible with both the window and building materials for long-lasting protection.

Properly sealing windows in a metal building is pivotal for reinforcing insulation and preventing water damage. Metal building windows, a critical component of the structure, require an airtight seal to maintain energy efficiency and keep the elements out. Homeowners and contractors aim to achieve a durable seal that can withstand the rigors of temperature shifts and environmental conditions.

By using the correct sealant and tools for the job, you create a barrier that enhances the building’s overall performance. This task not only secures the windows but also contributes to the longevity and sustainability of the structure. A well-sealed window can result in significant cost savings on energy bills and maintenance over time. Following the right sealing process is essential for anyone looking to protect their investment and maintain a comfortable indoor environment within a metal building.

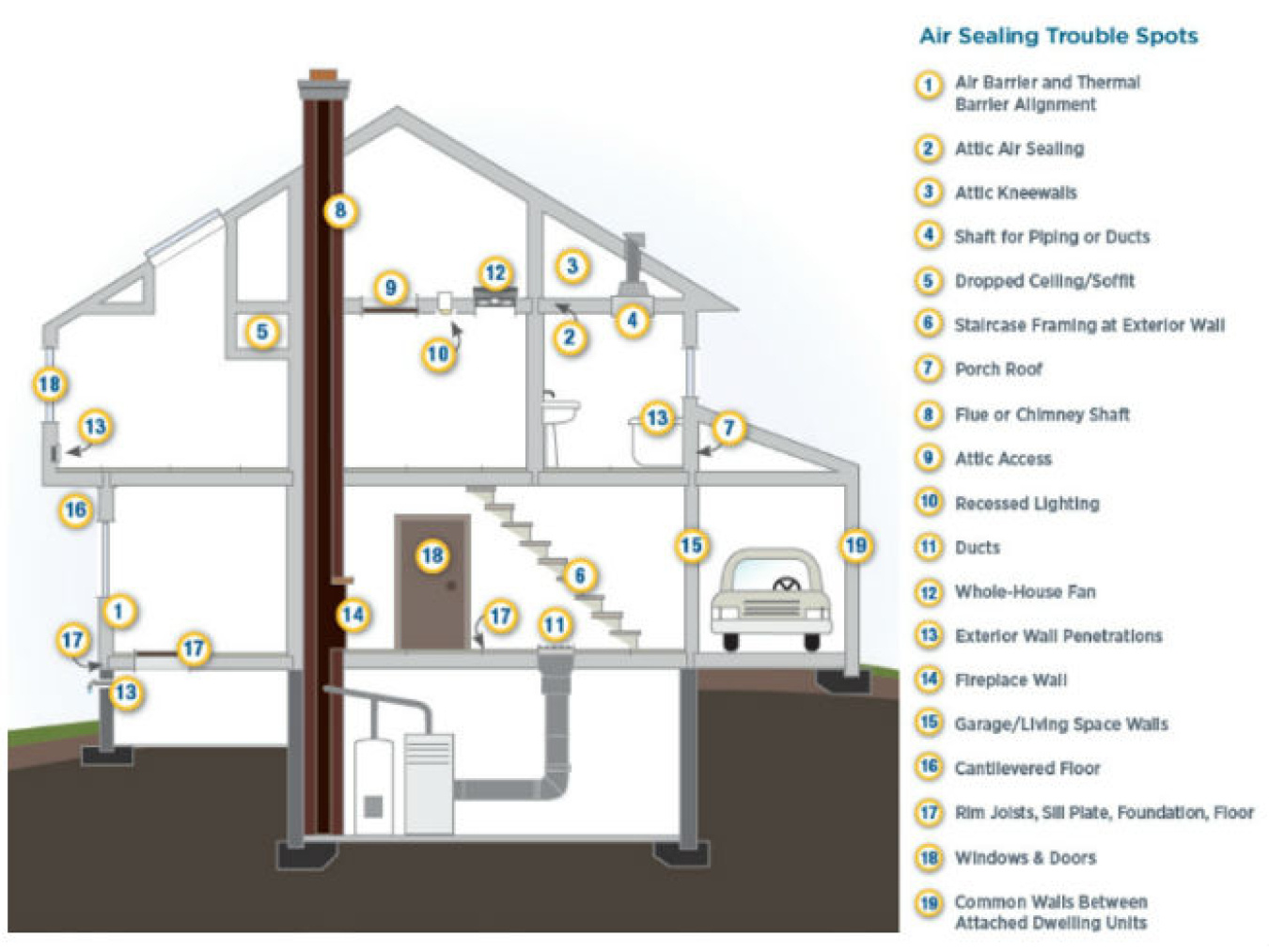

Credit: www.energy.gov

The Importance Of Airtight Metal Window Seals

Sealing windows in metal buildings ensures comfort and energy efficiency. Proper seals keep out unwanted drafts and water. Effective sealing techniques can save money and protect your interior from the elements. Explore the essentials of creating airtight window seals for your metal building.

Understanding

Strong window seals are crucial for climate control and reducing energy costs. An airtight seal:

- Stops air leaks, keeping indoor temperatures stable.

- Prevents moisture which can cause mold and rust.

- Reduces noise for a quieter indoor environment.

- Keeps out insects and small pests.

Correct sealing materials and methods guarantee these benefits.

Identifying Common Issues With Metal Building Window Seals

Deterioration of window seals is common in metal buildings. Signs of a faulty seal include:

| Signs of Faulty Seal | Potential Causes |

|---|---|

| Water leaks | Broken or cracked seals |

| Visible gaps | Shrunken or displaced sealant |

| Drafts around window | Age or weather damage |

| Increased energy bills | Heat loss through window frames |

Regular inspections can catch these issues early to maintain seal integrity.

Materials And Tools Required For Sealing Windows

Getting ready to seal your metal building windows? The process begins with gathering the right materials and tools. Proper sealing can prevent leaks, drafts, and protect your building from the elements. In this section, we’ll cover the essentials to ensure a solid, weatherproof seal around your windows.

Choosing The Right Sealant For Metal Surfaces

Selecting the appropriate sealant is critical for a durable bond with metal surfaces.

- 100% Silicone: Weatherproof and flexible, resists shrinkage and cracking.

- Polyurethane: Strong adhesion, perfect for areas with movement and temperature changes.

- Butyl Rubber: Excellent for sealing joints, remains pliable for a long period.

Essential Tools For The Sealing Process

With the right tools, application is easier and cleaner.

- Caulk Gun: Ensures even distribution of sealant.

- Utility Knife: For opening the sealant tube; precise cuts in the sealant.

- Cleaning Supplies: Alcohol wipes or a solvent to clean the window surface before applying sealant.

Additional Materials To Enhance Seal Longevity

Ensure your seal withstands time and weather with these extras:

- Backer Rod:

- Fills large gaps before sealing, saving sealant, and providing support.

- Foam Tape:

- Acts as a first layer of insulation and helps in even application of the sealant.

- Weatherstripping:

- Adds an extra barrier to elements, enhancing the longevity of the seal.

Step-by-step Guide To Sealing Windows

Ensuring your metal building windows are well-sealed is crucial for energy efficiency and comfort. From preparing the surface to applying the sealant, this guide leads you through a simple, yet effective process to seal your metal building windows.

Preparing The Window Area For Sealing

Clean surroundings and remove old sealant for a fresh start. Here’s how:

- Inspect the window frame for damage and repair if needed.

- Wipe down the area with a damp cloth to remove dust and dirt.

- Use a putty knife or scraper to remove any old caulk or sealant, ensuring a smooth surface.

- Apply rubbing alcohol to a clean cloth to disinfect and promote better sealant adhesion.

Applying The Sealant: Techniques For A Smooth Finish

With your surface prepped, apply a bead of sealant:

- Cut the sealant tube tip at a 45-degree angle for easier application.

- Hold the caulking gun at a consistent angle and pace along the joint.

- Smooth the sealant with a wet finger or tool for a clean, finished look.

Work in small sections for control. Let the sealant dry according to the manufacturer’s instructions.

Ensuring A Complete Seal: Tips And Tricks

Take extra steps to guarantee a complete seal around your metal building windows:

- Check for gaps or bubbles in the sealant and fill them promptly.

- Use masking tape around the edges of the frame for straight lines.

- Allow the sealant to cure properly without exposing it to moisture or extreme temperatures.

Regular inspections and touch-ups keep windows airtight. Follow these methods to maintain a durable seal over time.

Post-sealing Considerations

Successfully sealing around metal building windows creates a weatherproof barrier. Yet, the job doesn’t end there. Ensuring sealants cure properly, testing for airtightness, and ongoing maintenance play crucial roles.

Curing Time And Conditions For The Sealant

Sealant curing is vital for creating a lasting seal. After application around windows, the product needs set conditions to harden.

Follow these steps:

- Check the sealant’s label for specific curing times.

- Avoid direct water exposure until the product fully cures.

- Ensure the area stays dry and within the recommended temperature range.

Testing For Airtightness After Sealing

Confirming airtight seals helps maintain energy efficiency. Perform a simple test:

- Close all windows and doors in the building.

- Turn on exhaust fans or a blower door system.

- Light an incense stick and hold it near the sealed window edge.

- Observe the smoke; steady streams indicate leaks.

Maintenance Tips To Preserve Seal Integrity

Regular maintenance ensures the longevity of the seal. Implement these tips to avoid frequent repairs:

| Action | Purpose |

|---|---|

| Clean the sealed areas. | Removes debris and buildup that can wear down sealant. |

| Inspect seals seasonally. | Identifies early signs of wear or damage for timely repairs. |

| Keep chemicals away. | Prevents degradation from harmful substances. |

By focusing on post-sealing considerations, your metal building windows will feature strong, enduring seals that withstand the elements and time.

Troubleshooting Common Sealing Problems

Troubleshooting common sealing problems keeps your metal building efficient and weatherproof. Whether dealing with a draft or water leak, solutions exist to mend these issues effectively. Sealant issues, air leaks, and unusual window sizes can challenge the integrity of your building. Focus on these solutions to ensure a well-sealed environment.

Addressing Sealant Shrinkage And Cracking

Sealant failure can lead to costly repairs if not fixed promptly. Check sealant regularly for signs of wear. Look for areas that appear to shrink or crack. These are immediate red flags indicating the sealant is losing its efficacy.

- Choose a high-quality elastomeric sealant. It allows for movement and adjusts to changing temperatures.

- Remove old sealant carefully. Use a reliable tool to avoid damaging window frames.

- Apply sealant evenly. Ensure no gaps are left along the edges.

Preventing And Fixing Air Leaks

Air leaks increase energy bills and reduce comfort. To combat this, assess the insulation around windows. Feel for drafts and listen for whistling sounds. These signs point to air leaks.

- Install weatherstripping. This creates a tight barrier against air flow.

- Use spray foam for larger gaps. It expands to fill spaces where air might escape.

- Check the sealant’s application. Ensure a watertight seal around the window frame.

Strategies For Dealing With Difficult Window Shapes Or Sizes

Unique window configurations require special attention. They often challenge standard sealing practices. Yet, proper sealing is achievable with the right approach.

| Window Shape/Size | Strategy |

|---|---|

| Rounded or Arch | Use flexible sealing strips that curve with the window’s shape. |

| Oversized windows | Apply extra sealant and consider sectional weatherstripping for a better fit. |

| Narrow frames | Select a thin, paintable sealant for a discrete look that seals effectively. |

Professional Vs. DIY Sealing: Evaluating Your Options

Sealing around metal building windows is crucial for energy efficiency and preventing water damage. The choice between professional services and a do-it-yourself approach depends on various factors.

When To Consider Hiring A Professional

- Complex installations: Custom or large-scale window designs often require specialized knowledge.

- Limited experience: If you lack DIY skills, a professional ensures a reliable seal.

- Time constraints: Pros can complete the job quickly and efficiently.

Cost-benefit Analysis Of DIY Sealing

| DIY Sealing | Benefits | Costs |

|---|---|---|

| Materials | Lower expenses | Initial purchase |

| Time | Flexible schedule | Possible learning curve |

| Quality | Personal satisfaction | Inconsistent finishes |

Legal And Warranty Implications Of Self-sealing

Warranty: Check if DIY work affects window warranties. Many companies require professional installation for full coverage.

Building codes: Ensure compliance with local regulations. Non-professional work may violate codes, leading to penalties.

Insurance: Incorrect sealing could impact claims. Professional work usually comes with an insurance-backed guarantee.

Frequently Asked Questions

How Do You Seal A Metal Window Frame?

Clean the metal window frame thoroughly. Apply a bead of silicone caulk around the edges. Smooth the caulk with a wet finger for a tight seal. Allow it to dry completely before closing the window.

What Is The Best Sealant For Metal Building Windows?

The best sealant for metal building windows is a high-quality polyurethane or silicone-based product. These sealants provide strong adhesion, durability, and flexibility, ensuring a watertight seal against weather elements. Choose one designed for exterior use and compatible with metal surfaces.

How Do You Seal Around A Metal Building?

To seal around a metal building, clean the surface and ensure it’s dry. Apply weatherproofing caulking around base rails, windows, and doors. Use foam closure strips under roof and wall panels. Install base trim to prevent water ingress, and add sealant tape at panel overlaps for extra protection.

How Do You Keep Water Out Of Metal Buildings?

To prevent water intrusion in metal buildings, install proper insulation, use sealants around openings, ensure correct flashing and gutter installation, and maintain a sloped roof for optimal drainage. Regular inspections for damage can also help keep water out.

What Materials Are Needed To Seal Metal Windows?

Sealing metal building windows requires a high-quality, weather-resistant caulk, backer rod, and potentially flashing depending on the window design.

Conclusion

Sealing your metal building windows is crucial for energy efficiency and weatherproofing. With the right materials and techniques, you can prevent drafts and moisture damage effectively. Remember, a tight seal ensures durability and comfort. For any further assistance, feel free to consult a professional.

Take the step today for a cozier, more secure building.

I am Robert Sandin, a professional sealing expert with a diverse range of expertise. From concrete to various other materials, I possess in-depth knowledge and experience in the art of sealing. On my website, I offer valuable tips and expert recommendations on sealing techniques and products for different materials. Whether it’s concrete, wood, metal, or more, I am committed to providing you with the guidance you need for successful sealing projects.