How To Seal Foam Board Seams Projects: Quickly and Easily?

Clean all the joints and seams of foam boards properly. Apply several layers of thin beads of low-expansion foam. Then, smooth out the spray foam and trim the excess.

Next, apply polypropylene sheathing tape by cutting it appropriately based on the seam’s length and width. Inspect the result and make any corrections if needed.

Using the right product and correct method is crucial to give your foam board long-lasting protection. Stay with me until I finish to get a complete overview of how to seal foam board seams.

Why Properly Sealing Foam Board Seams is Crucial & How to Do It?

Foam boards have become common for household wall systems. However, sealing the joints and seams between the panels is necessary to create an air and moisture infiltration barrier in the wall system. It will ensure no air leaks and improve the insulation’s effectiveness.

The following are the sequential steps to seal foam board joints.

Step: 01—Prepare The Work Surface

Before sealing the foam board seams, clean them appropriately. Remove all the dust, dirt, moisture, and grease from these seams.

Some foam boards may release fumes. It is best to work in a well-ventilated area. Also, you want to wear a protective mask and hand gloves.

Step: 02— Apply Low-Expansion Spray Foam

Why should you choose a low-expansion spray foam over high-expansion options? The simple answer is its decent flowability. It appears cost-effective, too.

Shake the foam spray container vigorously for at least 30 seconds. Now, place the foam gun on the foam container.

Apply a light bead of low-expansion foam into the seams. If it is necessary, add another layer.

Applying several layers of thin beads of low-expansion foam is better than filling the entire gap.

This safe practice will save you from adding the foam solution to the unwanted area. This will save you valuable time, money, and effort.

Step: 03— Smooth And Dry The Spray Foam

Now, grab a foam board scrape or putty knife. Then, carefully smooth and level the sprayed foam. It will ensure proper adhesion of the spray foam and fill any voids or gaps.

Next, allow the solution to dry properly based on the manufacturer’s recommendation.

Usually, low-expansion spray foams take between 5 and 60 minutes to become touch-dry. But the duration can be 8 to 24 hours for a complete cure.

Of course, you can’t ignore the temperature, surrounding environment, humidity, spray foam formula, and thickness level.

Step: 04— Trim Excess Spray Foam

Once the spray foam is cured, inspect how much extra foam is outside the foam board joints.

Grab a serrated bread knife, flexible scraper blade, or foam saw to trim any excess foam that may have expanded beyond the foam board seams.

These handy tools are excellent for trimming small pieces of foam. Make sure the spray foam is strong enough to cut. Otherwise, it will stick into the cutter.

Step: 05— Apply Polypropylene Sheathing Tape

For added protection, it is a good rule of thumb to apply polypropylene sheathing tape.

This high-performance seam sealing tape has aggressive acrylic adhesive and can resist extreme temperatures. Cut strips of polypropylene sheathing tape as the seam’s length and width.

Apply the tape directly over the seam and press it firmly to maintain a decent bond with the foam boards and the cured spray foam.

Make sure the tape extends slightly beyond the foam boards to provide a complete seal.

Step: 06—Smooth And Level The Tape

Grab a small roller or use your hand to smooth down the polypropylene sheathing tape.

There should not be any air bubbles. Otherwise, it will compromise the seal’s integrity, allowing air and moisture infiltration.

Maintain a tight seal. Pay attention to the edges to prevent any potential air or moisture infiltration. Apply the tape to all seams one by one.

Step: 07— Inspect and Repeat

After taping all the joints and seams, carefully inspect for all your work. If necessary, take a break before checking it.

There should not be any voids or holes between the seals. Repeat the same sealing method if you notice any spot requiring additional sealing.

What Can I Use To Seal Foam Board?

When it comes to sealing foam boards, a huge number of options are available. Unfortunately, not all will give the same reliable result.

So, what is the best way to seal foam boards? After researching the market, I have figured out some of the best products for sealing foam board seams.

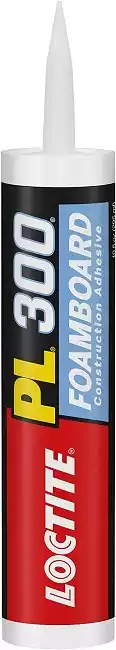

a) Foam-compatible Adhesive Caulks

You can’t use petroleum-based caulk because it will melt. Also, avoid choosing any low-VOC adhesives. They rarely work on foam boards.

Instead, you can use foam-compatible adhesive caulks like Loctite PL300 Foamboard Adhesive. The product takes only 20 minutes to dry.

It can add a strong and durable bond. This foam board caulk will adhere securely to the foam board upon application. It is resistant to water and weather.

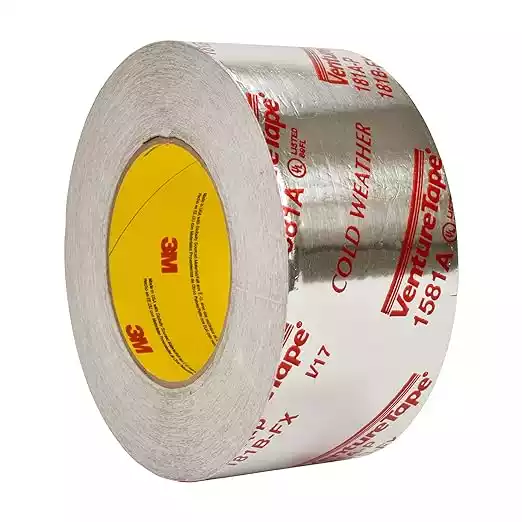

b) Polypropylene Sheathing Tape

Venture tapes are also a good choice for foam boards. , such as 3M Venture Tape. It has an excellent adhesion on foam boards.

You can use the product in demanding temperature and humidity applications. This user-friendly sealant tape bonds instantly on various types of surfaces.

Tyvek tapes and tuck tapes are the best tapes for foam board insulation. They hold pretty well on foam boards. This acrylic tape for foam board is highly waterproof and can create a continuous protective barrier against air and water infiltration. Make sure to keep it foil-faced for improved and long-lasting adhesion.

FAQ’s

What happens if I don’t seal the foam board seams properly?

Improper sealing can lead to moisture issues, reduced insulation, and potential mold growth. It can also compromise the board’s structural integrity.

Can I use a hairdryer to speed up the curing process of the sealant?

Not recommended. Rapid drying can result in uneven curing, compromising the seal’s strength.

Do temperature and humidity affect the sealing process?

Yes. High humidity can delay drying, and extreme cold can affect adhesion. Always work under recommended conditions.

What if I accidentally put too much sealant on a seam?

Wipe away excess while wet. If dried, trim carefully with a utility knife.

Can I reuse foam boards with sealed seams for different projects?

Reusing sealed boards can compromise their integrity. Always assess their condition before repurposing.

Final Words

The average lifespan of foam boards is anywhere between 5 to 10 years. But you can see premature failure if air and moisture leak occurs. That’s why sealing the seams and joints is necessary to protect the foam board for a long time.

I have already discussed how to seal foam board seams appropriately. It is best to use a compatible caulk and tape to provide the board with enhanced protection and long-lasting functionality.

I am Robert Sandin, a professional sealing expert with a diverse range of expertise. From concrete to various other materials, I possess in-depth knowledge and experience in the art of sealing. On my website, I offer valuable tips and expert recommendations on sealing techniques and products for different materials. Whether it’s concrete, wood, metal, or more, I am committed to providing you with the guidance you need for successful sealing projects.