How to Seal Gaps in Metal Building: Expert Tips & Techniques

Sealing gaps in metal buildings is straightforward. You need the right tools and materials.

Metal buildings can have gaps over time. These gaps may cause issues like water leaks, pests, and energy loss. Knowing how to seal gaps in metal building is crucial. It helps maintain the building’s integrity and efficiency. This guide will walk you through the steps.

You will learn the best methods and materials to use. By the end, you will be ready to tackle any gap in your metal building. Sealing gaps ensures your building stays strong and protected. Let’s get started on making your metal building secure and efficient.

Identifying Common Gaps

Sealing gaps in a metal building is crucial. Gaps allow air, water, and pests to enter. Identifying these gaps is the first step. You need to know where to look. Below we discuss common types of gaps and their causes.

Types Of Gaps

There are several types of gaps in metal buildings. Each type needs specific attention.

First, panel gaps are common. They occur where metal panels meet. These gaps can be small or large.

Second, door and window gaps are frequent. Poor installation or wear and tear can cause these gaps.

Third, roof gaps can be problematic. They often appear where the roof meets the walls. Leaks are a typical result of these gaps.

Causes Of Gaps

Gaps in metal buildings have various causes. It’s important to understand them.

First, poor installation is a major cause. If panels are not aligned correctly, gaps appear.

Second, weather changes can cause gaps. Metal expands and contracts with temperature. Over time, this movement creates gaps.

Third, building settling is another factor. As the ground shifts, the building may develop gaps.

Lastly, wear and tear contribute to gaps. Over time, metal components degrade. Regular inspections can help catch these early.

Credit: www.youtube.com

Essential Tools And Materials

Use caulking guns and silicone sealants for sealing gaps in metal buildings. Ensure surfaces are clean and dry before applying.

Sealing gaps in metal buildings is crucial for maintaining their structural integrity and ensuring energy efficiency. To achieve the best results, it’s essential to have the right tools and materials. In this section, we’ll cover the indispensable items you need to successfully seal those gaps.

Sealants

Choosing the right sealant is critical. There are different types for various applications. Silicone sealants are popular for their flexibility and durability. They can withstand extreme temperatures and resist moisture.

Polyurethane sealants are another great option. They offer strong adhesion and are perfect for sealing larger gaps. Consider using butyl tape for an easy and effective solution for seams and joints.

Don’t forget to check the compatibility of the sealant with the metal surface to ensure long-lasting results.

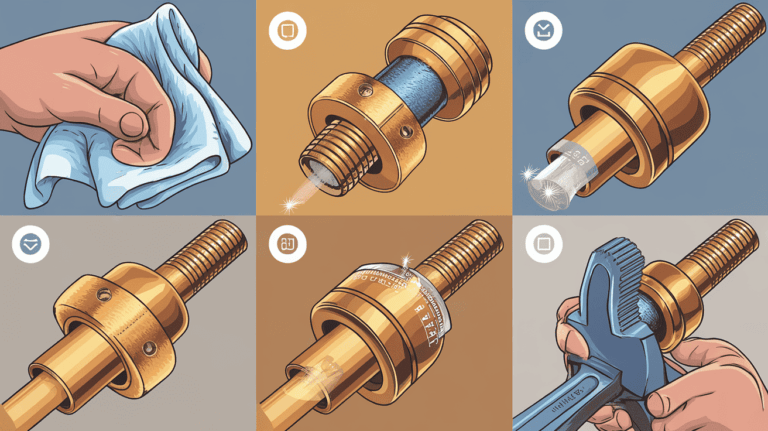

Application Tools

Having the right tools makes the job easier and more efficient. A caulking gun is a must-have for applying sealants smoothly. It helps control the flow and ensures a precise application.

A putty knife or scraper is useful for removing old sealant and preparing the surface. This tool helps create a clean base for the new sealant to adhere to.

For larger gaps, consider using a foam backer rod. It provides extra support and ensures the sealant fills the gap completely.

Don’t forget safety gear like gloves and goggles. Protecting yourself is just as important as getting the job done right.

Have you ever tried sealing gaps without the right tools? It can be frustrating and lead to poor results. Ensuring you have these essential tools and materials can make all the difference.

Preparing The Surface

Before sealing gaps in your metal building, proper surface preparation is crucial. This ensures the sealant adheres well and lasts longer. A clean, smooth surface helps prevent issues in the future. Follow these steps to prepare the surface effectively.

Cleaning The Area

First, clean the area around the gap. Remove any dirt, dust, and debris. Use a brush or a cloth to wipe the surface. For stubborn dirt, use mild soap and water. Rinse well and let the area dry completely. A clean surface helps the sealant stick better.

Removing Old Sealant

Next, remove any old sealant from the gap. Use a putty knife or a scraper. Carefully scrape away the old sealant without damaging the metal. If the old sealant is hard to remove, use a sealant remover. Apply the remover, wait a few minutes, and then scrape again. Once all the old sealant is gone, wipe the area clean. This step ensures a fresh start for the new sealant.

Choosing The Right Sealant

Choosing the right sealant is crucial for sealing gaps in metal buildings. Each sealant type has unique properties, making it suitable for specific applications. This section will help you understand the best sealant for your needs.

Silicone Sealants

Silicone sealants are popular for their flexibility and durability. They can withstand extreme temperatures, making them ideal for metal buildings. Silicone sealants are also resistant to UV rays, which means they won’t degrade in sunlight. These sealants are perfect for outdoor applications. They adhere well to metal surfaces, ensuring a long-lasting seal.

Polyurethane Sealants

Polyurethane sealants offer excellent adhesion and elasticity. They are known for their strong bonding properties. These sealants are resistant to abrasion and impact. This makes them suitable for areas with high wear and tear. Polyurethane sealants can also handle slight movements in the metal structure. This flexibility helps maintain the seal over time.

Application Techniques

Sealing gaps in metal buildings involves using high-quality caulk or foam sealant. Apply the sealant evenly to ensure a tight seal. This prevents leaks and improves energy efficiency.

Sealing gaps in your metal building is essential to maintain its integrity and prevent issues like water leakage, pest infestation, and heat loss. Understanding the right application techniques is key to ensuring a long-lasting seal. Let’s dive into two effective methods: caulking and foam insulation.

Caulking

Caulking is a straightforward and efficient way to seal small gaps and cracks in your metal building.

First, clean the area thoroughly to remove dirt and debris. This ensures the caulk adheres properly.

Next, choose the right type of caulk. Silicone-based caulk is ideal for metal as it is durable and flexible.

Apply the caulk using a caulking gun, moving steadily along the gap. Ensure you fill the entire space without over-applying.

Smooth the caulk with a damp finger or a caulk-smoothing tool to create a clean finish. This step also helps to push the caulk deeper into the gap.

Let the caulk dry completely. Check the product instructions for the recommended drying time.

Foam Insulation

Foam insulation is excellent for larger gaps and offers added insulation benefits.

Before applying foam insulation, clean the area thoroughly. Dust and debris can prevent proper adhesion.

Choose a spray foam designed for metal buildings. These products expand to fill gaps and provide a tight seal.

Wear gloves and protective eyewear. The foam can be sticky and hard to remove.

Shake the can well before use. Insert the nozzle into the gap and apply the foam. It will expand, so use it sparingly.

Allow the foam to cure as per the manufacturer’s instructions. Once dry, trim any excess with a utility knife.

Consider applying a sealant over the foam for added protection and durability.

### Your Turn

Have you ever sealed gaps in your metal building? What techniques worked best for you? Share your experiences in the comments below. Your insights can help others tackle their sealing projects with confidence.

Credit: www.titanapplicators.com

Sealing Roof Gaps

Sealing gaps in a metal building’s roof is crucial to prevent leaks and improve insulation. Use high-quality sealants and proper tools to ensure a tight fit. This helps maintain the building’s integrity and energy efficiency.

### Sealing Roof Gaps

Sealing roof gaps is essential for maintaining the durability and longevity of your metal building. Unsealed gaps can lead to leaks, which may cause significant damage over time. By addressing these issues promptly, you can prevent costly repairs and ensure your structure remains in top condition.

### Inspecting Roof Seams

Before you start sealing roof gaps, thoroughly inspect the roof seams. This step is crucial because it helps you identify where the gaps are and how extensive they might be.

Look for visible cracks, holes, or any signs of wear and tear. Pay special attention to areas around fasteners and joints, as these spots are prone to developing gaps.

If you notice any rust, make sure to address it first. Rust can weaken the metal and make sealing less effective. A quick scrub with a wire brush can remove surface rust, but deeper corrosion may need professional attention.

### Applying Roof Sealant

Once you’ve inspected the roof seams, it’s time to apply the sealant. Choose a sealant that’s specifically designed for metal roofs to ensure the best adhesion and durability.

Start by cleaning the area around the gap with a cloth to remove any dirt or debris. This ensures the sealant sticks properly.

Apply the sealant generously over the gap, making sure to cover the entire area. Use a brush or a caulking gun, depending on the type of sealant you have.

Smooth the sealant with a putty knife to ensure even coverage. This step helps the sealant penetrate deeper into the gap and creates a more secure seal.

Allow the sealant to dry completely before exposing it to rain or other elements. Drying times can vary, so check the manufacturer’s instructions for the best results.

Sealing roof gaps might seem like a daunting task, but it’s manageable with the right approach. Have you ever tried sealing gaps in your metal building? What challenges did you face, and how did you overcome them? Share your experiences in the comments below!

Sealing Wall Gaps

Sealing wall gaps in a metal building is crucial to maintain insulation, prevent pest infestations, and improve energy efficiency. If you’ve noticed drafts or small critters sneaking in, it’s time to tackle those gaps. Here’s a guide to get you started.

Filling Wall Cracks

First, identify the cracks. Walk around your building and inspect the walls thoroughly. Look for visible gaps, especially near corners and joints.

Use a wire brush to clean out any debris or rust within the cracks. This ensures that the sealant adheres properly. A clean surface is key for a long-lasting seal.

Apply a high-quality metal sealant. Silicone or polyurethane sealants are excellent choices. They are flexible and durable, which helps them last through weather changes.

Smooth out the sealant with a putty knife or your finger. Make sure the sealant fills the crack completely. A smooth finish will give a professional look and enhance its effectiveness.

Using Weatherstrips

Weatherstrips are fantastic for sealing larger gaps around doors and windows. They are easy to install and highly effective at blocking drafts.

Choose the right type of weatherstrip. Self-adhesive foam or rubber strips are popular and effective. Measure the gap to ensure you get the correct size.

Clean the area where you will apply the weatherstrip. Remove dirt, dust, and old adhesive. This helps the weatherstrip stick better and last longer.

Cut the weatherstrip to the desired length. Peel off the backing and press it firmly into place. Make sure it fits snugly without leaving gaps.

Have you tried sealing gaps in your metal building? What challenges did you face? Share your thoughts in the comments below!

Maintaining Sealed Gaps

Keeping gaps in metal buildings sealed is vital. It prevents water leaks, pest invasions, and energy loss. Regular maintenance ensures the longevity of the seal. This section explains how to maintain these sealed gaps effectively.

Regular Inspections

Inspect your building every few months. Check for any visible damage or wear. Pay special attention to areas exposed to harsh weather. Look for cracks, holes, or any broken sealant. Use a flashlight to examine darker areas. Early detection can save on costly repairs.

Reapplying Sealant

Sealants can degrade over time. Reapply sealant where needed. Clean the area first to ensure a good bond. Remove old, cracked sealant with a scraper. Apply a fresh layer of high-quality sealant. Smooth it out evenly. Allow it to dry completely before inspecting again.

Credit: midweststeelcarports.com

Frequently Asked Questions

What Can I Use To Fill Gaps In Metal?

Use epoxy putty, welding, or metal filler to fill gaps in metal. These methods provide strong and durable repairs.

How To Seal Gaps In A Metal Shed?

To seal gaps in a metal shed, use a silicone sealant or expanding foam. Clean the area first. Apply the sealant evenly, covering all gaps. Let it dry completely for a weatherproof seal. This prevents water, pests, and drafts from entering.

Proper sealing extends the life of your shed.

What To Use To Seal A Metal Building?

Use silicone sealant or polyurethane caulk to seal a metal building. These materials provide durability and flexibility. Apply the sealant to joints, seams, and gaps. Ensure surfaces are clean and dry before application. Consider using foam closures for additional sealing on roof panels.

How Do I Stop Water From Coming Under My Metal Building?

Seal gaps with waterproof caulk. Install gutters and downspouts. Ensure proper drainage around the building. Use a moisture barrier. Maintain regular inspections for leaks.

Conclusion

Sealing gaps in a metal building ensures better insulation and protection. It keeps pests and moisture out. Use quality sealants for best results. Regular checks help spot new gaps early. A well-sealed building lasts longer. Plus, it saves on energy costs.

Follow these steps for a secure, efficient metal building. Your effort will pay off.

Hi Friends, I’m SealerMrinal, your go-to expert for all things sealing. With years of hands-on experience across a wide range of materials—concrete, wood, metal, and more—I bring deep knowledge and practical insights into every sealing project. On my website, I share expert tips, proven techniques, and product recommendations to help you get the best results. Whether you’re tackling a DIY project or seeking professional-grade advice, I’m here to guide you through the art and science of effective sealing.