What Can I Use to Seal a Plastic Gas Tank: Top Fixes!

To seal a plastic gas tank, use a specialized plastic gas tank repair kit or epoxy sealant designed for plastic. For a temporary fix, consider a plastic-compatible adhesive or tape.

Sealing a plastic gas tank is a task that requires attention to detail and the right materials. Whether it occurs due to wear and tear or an unfortunate incident, a leak in your plastic gas tank needs immediate repair to prevent fuel loss and potential hazards.

A well-selected repair kit can effectively mend cracks or holes, ensuring the safety and efficiency of your vehicle. The market offers various products tailored for this purpose, from epoxy sealants to complete repair kits, that bond with plastic to create a durable seal. It’s essential to choose a product that is resistant to gasoline and other chemicals typically found in a vehicle’s fuel system. Proper application of these products can restore the integrity of your gas tank, keeping you moving without leaks.

Introduction To Plastic Gas Tank Repairs

Plastic gas tank repairs are a critical task for vehicle maintenance. Over time, tanks can suffer damage. Knowing how to seal them is essential. This guide provides clear steps on fixing these issues.

Overview Of Plastic Gas Tank Vulnerabilities

Plastic gas tanks are common in various vehicles. They are light and rust-resistant. Yet, they can develop cracks and holes. Causes include accidents, stress, and environmental factors. Understanding these risks is vital.

- Physical Impact: Collisions can cause immediate damage.

- Chemical Reactions: Certain substances may weaken the plastic.

- Wear and Tear: Over time, even high-quality tanks can degrade.

Importance Of Properly Sealing A Plastic Gas Tank

A well-sealed tank is crucial for safety. It prevents leaks and protects the environment. Fuel efficiency also improves. The right sealant can make a huge difference. It extends the tank’s lifespan.

| Benefits | Details |

|---|---|

| Safety | Mitigates fire hazards and health risks. |

| Environment | Prevents fuel spillage and pollution. |

| Performance | Ensures consistent fuel delivery and vehicle operation. |

Assessing The Damage

When it comes to maintaining your vehicle, addressing fuel tank issues promptly ensures safety and longevity. Assessing the damage to your plastic gas tank is the crucial first step in the sealing process. It doesn’t just save you time and resources but also prevents minor issues from evolving into major headaches.

Identifying The Type And Extent Of The Damage

Start your inspection by thoroughly cleaning the area around the damage. Look for cracks, holes or any signs of wear and tear. Use a flashlight and a mirror to check hard-to-see sections. Identifying the damage type is vital for choosing the right sealant. Check if the damage is a surface scratch, a deep crack, or a puncture. Note down the size and location.

- Surface scratches: Minor and often only affect the appearance.

- Deep cracks: More severe, risking the integrity of the tank.

- Punctures: Small but can lead to significant fuel loss and require immediate attention.

Preparation Steps Before Sealing

Proper preparation is key to ensuring a lasting seal. First, empty the gas tank completely. This reduces risk of fire and allows better access to the damaged area.

- Drain the tank and let it dry.

- Clean the affected area with soapy water.

- Rinse thoroughly and dry with a clean towel.

- Sand the area with fine-grit sandpaper to create a rough surface for better adhesion.

- Wipe the sanded area with a degreaser to remove any oily residue.

Only once these steps are completed, you’re set to apply a sealant. Ensure you wear gloves and work in a well-ventilated space. The right preparation leads to a successful seal and a gas tank ready to hold fuel securely once again.

Sealant Options For Plastic Gas Tanks

Commercial Sealants And Their Applications

Commercial sealants come in various forms, ranging from putties to sprays.

| Product Type | Application | Use Case |

|---|---|---|

| Putty | Hand-molded | Fix small leaks quickly |

| Spray | Evenly coated | Seal inaccessible areas |

Select a product that’s suitable for plastic and resistant to gasoline. Always use products in a well-ventilated area and according to the manufacturer’s instructions.

Diy Repair Methods

Fixing a plastic gas tank need not be daunting. With the right materials and a bit of patience, you can seal it like a pro.

Step-by-step Guide To Applying Epoxy

Epoxy is your best friend when it comes to sealing plastic. It creates a tough, leak-proof barrier.

- Clean the area around the leak. No grease should remain.

- Mix the epoxy according to the instructions.

- Apply it over the leak. Ensure you cover it well.

- Let it cure. Drying times vary, so check the product guide.

Tips For Successful Plastic Welding

- Select the right kind of plastic rod for welding.

- Heat both the rod and the tank evenly.

- Press the melting rod into the crack. Go slowly and steadily.

- Allow it to cool off. Don’t touch until it’s solid.

Common Mistakes To Avoid In Diy Repairs

Safety first! Wear gloves and work in a well-ventilated area. Avoid these pitfalls:

- Skipping the cleaning step can cause weak seals.

- Applying epoxy on wet surfaces won’t work.

- Using the wrong type of epoxy or welding rod may lead to failure.

- Hurrying the curing process can create new leaks.

Professional Repair Solutions

Dealing with a leaking plastic gas tank is no small feat. Proper sealing is vital for safety and performance. Many car owners grapple with the decision to fix it themselves or seek professional aid. In some cases, professional help could be the best course of action. Let’s explore when to enlist the expertise of a professional, what they offer, and the financial implications of DIY versus a pro job.

When To Seek Professional Help

Your plastic gas tank might need a professional touch under certain circumstances. Seek expert assistance if the crack is large or if the tank is extensively damaged. Professionals have the right tools and materials to ensure a safe and durable repair.

Services Offered By Professionals

- Thorough inspection: Experts start with a detailed assessment to pinpoint all issues.

- Advanced sealing techniques: They use industry-grade sealants for a lasting solution.

- Quality testing: Post-repair testing ensures the tank is safe for use.

- Warranty on repair: Many offer a guarantee on the work performed.

Cost-benefit Analysis Of Diy Vs Professional Repairs

| DIY Repair | Professional Repair |

|---|---|

| Lower upfront cost | Higher upfront cost |

| Time-consuming | Time-efficient |

| Potential for errors | Professional quality |

| No warranty | Work is guaranteed |

Deciding between a DIY or professional repair isn’t just about the cost. Consider safety, time investment, and long-term performance. Remember, a professionally sealed gas tank can save you from future repair costs and provide peace of mind.

Maintaining A Sealed Plastic Gas Tank

Keeping a plastic gas tank leak-free is crucial. A well-sealed tank is safer and lasts longer. This section covers important maintenance tips. These ensure your plastic gas tank remains in top condition.

Long-term Care Tips

Regular care is key to a plastic gas tank’s longevity. Simple steps can prevent big issues. Here are the best long-term care tips:

- Regular Cleaning: Keep the exterior dirt-free. This avoids abrasions.

- Proper Installation: Ensure all fittings are tight. This prevents leaks.

- Use Compatible Materials: Only use sealants made for plastic. This stops chemical damage.

- Check Ventilation: Ensure the tank breathes. This stops pressure build-up.

Monitoring For Future Issues

Vigilance finds small problems before they grow. Look for these signs:

| What to Monitor | Signs of Trouble |

|---|---|

| Sealant Condition | Cracks or peeling |

| Fittings and Hoses | Loose connections or wear |

| Surface Damage | Scratches or impacts |

| Fuel Quality | Discoloration or odor changes |

Enhancing Durability With Preventive Measures

Preventive steps guard against future damage. They boost tank resilience. Follow these measures:

- Avoid Direct Sunlight: UV rays can weaken plastic.

- Use Proper Sealants: Choose sealants designed for plastic tanks specifically.

- Handle with Care: Avoid drops or hard impacts.

- Store Sensibly: Keep in a cool, dry place when not in use.

Best Practices to Fix Your Plastic Gas Tank Leak

The journey to repair a plastic gas tank brings us to the most crucial stage: sealing it properly. Sealing ensures durability and safety. We discussed various methods that provide a sturdy solution to potential leaks. Now, it’s time to summarize the information and outline maintenance tips that can extend the lifespan of your gas tank.

Recap Of Effective Sealing Techniques

We explored several ways to seal a plastic gas tank. Epoxy, plastic welding, and commercial sealants stood out. Epoxy creates a hard layer over cracks. With plastic welding, we melt a similar plastic into the crack. Commercial sealants are easy to apply. Each method has pros and cons. Your choice depends on the severity of the damage and the tools available.

- Epoxy use requires thorough surface preparation.

- Plastic welding is best for larger cracks.

- Commercial sealants work well for quick fixes.

Final Recommendations For Gas Tank Maintenance

Regular inspection of your gas tank can save time and money. Look out for small leaks or damage. Use the right sealant for minor issues. For bigger concerns, seek professional help. Here are some maintenance tips:

- Check your gas tank regularly for any signs of wear.

- Clean the exterior surface to spot potential leak points.

- Handle your vehicle with care to avoid damage.

- Follow the manufacturer’s guidelines for maintenance.

Proper maintenance helps prevent the need for frequent repairs. A well-maintained gas tank is safe and reliable. Make sure to apply these tips and keep your vehicle running smoothly.

Frequently Asked Questions Of What Can I Use To Seal A Plastic Gas Tank

What Is The Best Sealant To Use On A Gas Tank?

The best sealant for a gas tank is a two-part epoxy putty specifically designed for gasoline resistance. Use a product rated for fuel tank repairs to ensure durability and safety.

Will Jb Weld Seal A Plastic Gas Tank?

JB Weld can seal a plastic gas tank if you use the correct product designed for plastic and follow the application instructions properly. Always ensure compatibility with fuel containers.

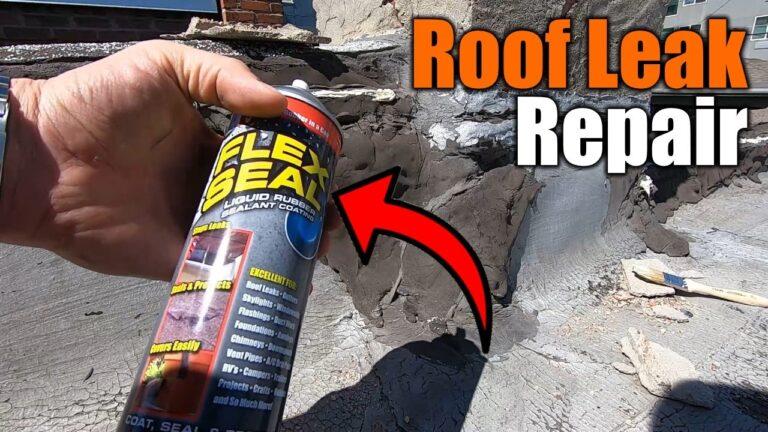

Will Flex Seal Seal A Plastic Gas Tank?

Flex Seal is not recommended for sealing plastic gas tanks; it’s designed for waterproofing and may not withstand fuel.

How Do You Fix A Crack In A Plastic Gas Tank?

Drain the fuel tank and clean the cracked area. Sand it lightly to create a rough surface for better adhesion. Apply a compatible plastic adhesive or epoxy to the crack. Let it cure as per product instructions before refilling with fuel.

What Seals Plastic Gas Tanks Effectively?

Suitable sealants for plastic gas tanks include epoxy compounds, specifically designed for plastic and fuel resistance.

Conclusion

Securing your plastic gas tank effectively is crucial for safety and performance. Opt for specialized sealants, like epoxy resins or fiberglass patches, designed for high durability and fuel resistance. Tackling leaks promptly ensures a smooth-running engine. Remember, the right sealant performs under pressure, just like your vehicle.

Safe travels!

Read More: How to Seal A Septic Tank Lid: 7 Proven Steps to Seal it Right

I am Robert Sandin, a professional sealing expert with a diverse range of expertise. From concrete to various other materials, I possess in-depth knowledge and experience in the art of sealing. On my website, I offer valuable tips and expert recommendations on sealing techniques and products for different materials. Whether it’s concrete, wood, metal, or more, I am committed to providing you with the guidance you need for successful sealing projects.