Unlocking the Secrets: What Can I Use to Seal Jesmonite?

When it comes to preserving the beauty and longevity of Jesmonite creations, the question of “What Can I Use To Seal Jesmonite?” arises. To seal Jesmonite effectively, you can use top-quality sealers like Flexiguard Sealer, Jesmonite Acrylic Sealer, or Penetrating Sealer.

These products safeguard Jesmonite surfaces from moisture, stains, and UV damage, ensuring long-lasting protection and aesthetics.

A huge number of sealers are available. But not all of them are compatible, effective, and durable. Here, I will walk you through some of the best Jesmonite sealers and how to use them.

What Is The Best Sealer For Jesmonite?

The following are the three best products for sealing a Jesmonite object.

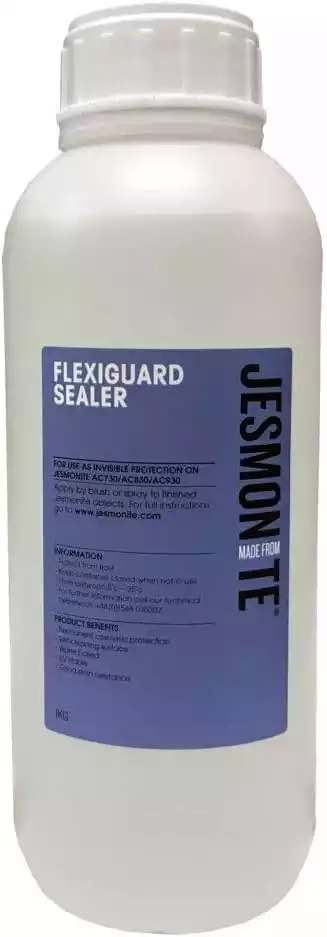

i) Flexiguard Sealer

Jesmonite is naturally porous because it absorbs moisture. Flexiguard Sealer is an effective sealant to protect the Jesmonite surface.

It has a solvent-formula to achieve faster cure times. Plus, this special sealing product is made from a stain-resistant formula to preserve aesthetics, durability, and functionality.

Even extremely cold and hot temperatures will cause minimum harm to the Jesmonite surface. It can withstand from -20°C to +350°C.

Besides, this sealing product has a low tendency to discoloration as you have to clean it less frequently.

It has hydrophobic and oleophobic capabilities, too. The product is less likely to give any scope for any ingrained soiling, mold, and fungal growth.

Flexiguard Sealer is compatible with a wide range of Jesmonite products, such as Jesmonite AC100, Jesmonite AC730, Jesmonite AC830, etc.

ii) Jesmonite Acrylic Sealer

Do you prefer a simple and versatile solution to add a coating to Jesmonite AC100, 200, or 300? You can use this sealer to provide a clear satin or matte finish on your Jesmonite surface.

Besides, adding a shiny layer on the Jesmonite object is possible. The average lifespan of this acrylic sealer can be anywhere between 6 to 10 years, depending on exposure severity.

You can use a brush, roller, or spray or apply the sealer on your Jesmonite object. Jesmonite acrylic sealer will ensure the natural thermal and moisture movement of Jesmonite to prevent unwanted cracking or delamination of the surface.

The material can freely expand and contract without constraints. You won’t have to worry about premature wear and tear.

iii) Penetrating Sealer

When it comes to protecting a Jesmonite from oil, water, and stains, a Jesmonite penetrating sealer appears to be a perfect choice.

This sealant product suits Jesmonite AC730, AC830, AC930, and even AC100. It forms a protective barrier against moisture, stains, and other contaminants.

This waterborne industrial sealer is also perfect for flex metal surfaces. It won’t affect the metallic exterior and protects the surface against corrosion.

Use a high-quality brush to apply penetrating sealer on a Jesmonite surface. It will help you achieve a more even and consistent application and get a uniform coverage.

The well-distributed bristle of the brush will allow the sealer to be worked into the pores of the Jesmonite effectively. You will see no visible brush marks or streaks.

How To Seal Jesmonite: A Beginner’s Guide?

Whenever it comes to sealing a Jesmonite surface, you want to follow a step-by-step guideline to achieve the best result.

Step: 01—Preparing The Jesmonite Surface

Before applying the Jesmonite sealant, cover all the areas where you don’t want to use the product. Otherwise, it will be hard to remove the sealer.

Another important thing is getting off any oil, contaminants, or grease from the Jesmonite object. It will ensure maximum adhesion strength and prevent any future damage or a bad seal.

Step: 02—Preparing The Jesmonite Sealant

Some Jesmonite sealants require diluting with water, and others don’t need any dilution.

When you are using any diluting-based product, make sure to mix the solution correctly by following the manufacturer’s instructions.

Grab a clear plastic that has a weighing scale. Add a particular amount of Jesmonite sealant depending on where you want to apply it.

Pour 10% of water inside the jug to dilute it. For instance, if you have added 20 grams of sealant, pour 2 grams of water.

But, the water percentage can be up to 20% depending on the porosity of the substrate.

Use a wooden mixing stick to mix the sealer and water appropriately. Avoid shaking it after mixing it appropriately.

Step 03—Applying The First Coating Of The Sealant

After properly preparing the Jesmonite sealer, apply it to the Jesmonite object. Use a brush or sponge to apply the sealant, as Jesmonite has a porous surface.

How many coats do you need to apply? Adding two or three thinner coats is better than a single heavier coat.

It ensures better coverage and distribution of the sealant over the surface. Plus, thin coats of sealant adhere better to the substrate than thick coats. It also dries or cures faster.

You can eliminate any brush or roller marks quickly. The overall finished result will be smoother and more visually appealing.

Step: 04—Applying The Next Coating Of The Sealant

It is best to wait at least two hours after applying the first coat. But the duration can be longer. Follow the manufacturer’s direction.

Before applying the second coat, the Jesmonite surface must be dry to the extent that it can be touched without leaving a mark.

When applying the second coat, you don’t need to dilute it with water. Use the sealant directly. But make sure the sealant is a bit thinner than the first coat. If it is necessary, add another coat.

Make sure to maintain at least two hours of break after applying the next coating. After applying several coatings, wait for 24 hours for the final cure.

FAQ’s

Can I use a spray sealant on Jesmonite?

Yes, spray sealants can be used, but ensure they are compatible with Jesmonite and apply evenly.

How often should I reseal my Jesmonite pieces?

The frequency of resealing depends on the type of sealant used and the environmental conditions to which the piece is exposed.

Can I use food-safe sealants on Jesmonite?

Yes, if you intend to use your Jesmonite piece for food-related purposes, ensure the sealant is food-safe.

Is it necessary to sand the Jesmonite before sealing?

Sanding ensures a smooth surface, allowing the sealant to adhere better, so it is recommended.

How can I achieve a glossy/matte finish?

The finish depends on the type of sealant used. Read the product description to choose the right one for your desired finish.

Conclusion

Are you still thinking of this question: What can I use to seal Jesmonite? I have already discussed top sealants you can use to seal any Jesmonite surface.

If you prefer any other product, ensure it is compatible with the Jesmonite. Otherwise, it won’t create an effective sealant.

One important point to remember is to apply the sealer correctly to get the best result. Let us know if you are using any other Jesmonite sealant.

I am Robert Sandin, a professional sealing expert with a diverse range of expertise. From concrete to various other materials, I possess in-depth knowledge and experience in the art of sealing. On my website, I offer valuable tips and expert recommendations on sealing techniques and products for different materials. Whether it’s concrete, wood, metal, or more, I am committed to providing you with the guidance you need for successful sealing projects.